You're attending your local car show looking for ideas for your own ride. Every time you see a vehicle with a glass like paint job, you stop and ask the owner "Who painted it?" Maybe you should be asking who color sanded and polished it.

The process of color sanding and polishing has been widely used for years by professional body shops to remove imperfections from a vehicle's freshly painted finish. Dust particles and small divots are things that are correctable by color sanding. Color sanding is also used for removing orange peal.

Orange peal is the term used to describe the bumpy surface of most painted finishes. It is referred to as orange peal because the paint surface looks like the surface of an orange, bumpy and uneven. Because of the make-up of today's urethane finishes, orange peal is almost unavoidable. The removal of these imperfections is what separates a normal paint job from an outstanding one.

Color sanding is certainly not an easy process, nor is it quick. It can take between 25 and 100 hours (yes 100 hours!) to complete a thorough job on an average sized automobile. It is time consuming because there are several steps involved in the process. It is also urged that persons who are not skilled in the process of machine polishing leave this procedure to a professional.

Getting Started: The first step in color sanding is to select the proper grit of color sanding paper for the operation. Color sanding paper comes in a variety of grits including 1000, 1200, 1500, 2000, 2500 and 3000 grit. The finer paper will sand the surface more smoothly, however it will take longer and will not cut the surface as sharply. In most cases, a standard procedure is to cut the surface with 1000 grit, followed with 1500 grit and finishing with 2000 grit. 1000 grit paper will cut the surface much more sharply and eliminate more orange peal than starting with 1500 or 2000. If the desire is to match a factory finish for a small panel repair rather than a complete repaint, than a finer paper would be more desirable.

Next, prepare a 5-gallon bucket with warm water and a few drops of car wash soap. The car wash soap will aid the water as a lubricant and allow the sanding paper to glide easily along the surface. Place several sheets of color sanding paper (of the proper grit) in the bucket and allow them to soak for at least 15 minutes. Soaking the color sanding paper will soften the paper and reduce any gouges caused by the paper being excessively rigid.

While the color sanding paper is soaking, thoroughly wash the vehicle to remove the surface dirt and contaminates that could damage the surface. Once the vehicle has been washed and properly dried, bring the vehicle indoors away from dust and direct sunlight.

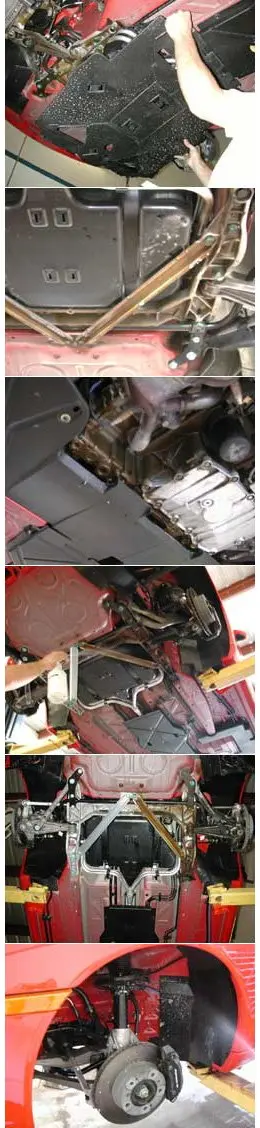

Sanding: With the color sanding paper properly softened and the vehicle washed, it is now time to start sanding. If the vehicle has been freshly painted, most trim will already have been removed. If not, remove any trim that can be removed without damage and tape off any trim that cannot.

Chose a sanding block that best suits the goal of the color sanding procedure. If the desire were to eliminate all orange peal and create a show car finish, the use of a hard sanding block would be best. A trick that works well is a standard 1-gallon paint stir stick cut just shy of the length of the paper. Soak the stick in the same bucket of water until it becomes slightly flexible and roll the paper around the stir stick. As the paper rounds the stick, the edges become slightly rolled and this eliminates any paper gouging marks. As the paper wears, simply tear off one side of the paper and flip over the block to a new section of paper. If the goal were to only eliminate some imperfections or to match a factory finish, the use of a rubber coated foam block would be best. This type of block will only reduce the amount of orange peal and would best match an original finish.

When sanding, it is best to sand in straight lines going in two directions to insure a flat finish. Use a method of diagonal patterns that oppose each other. Make sure to sand using only moderate pressure and allow the paper to do the work. While sanding use a terry cloth towel soaked in water to flush the sanding area while sanding is being performed. It is extremely important to allow plenty of water to flow over the sanding area.

The most important thing to remember when sanding is to listen for any particles under the paper. If any audible screeching or non-normal scratching is heard, wash the paper immediately and rinse the entire area. It is also important only to sand enough material from the vehicle to level out the finish. Going too far will result in "burning through" which is detrimental to the finish. To check the sanding progress, use a rubber squeegee to dry the surface. Inspect and sand areas that need more attention. If the sanding is started with 1000 grit, follow this step with a 1500 grit paper, and finish with 2000 grit using the same sanding process. If the goal is to only remove small imperfections, 1500-grit or finer paper may be a good choice for this procedure.

Trizact Method: 3M developed Trizact foam discs to remove imperfections and leave a uniform finish that easily polishes to a fine gloss. Trizact 3000 discs level evenly using special pyramid abrasives. Upon completion of sanding using a 1500 grit abrasive, following with the 3M Trizact 3000 foam disk will greatly reduce sand scratches. This product will begin to re-produce a gloss, diminishing sand scratches, and allow the polishing to be performed with greater ease. Use a 3M Hookit DA backing plate, with a pneumatic dual action sander, Spray a light amount of water to wet the surface. Sand in over-lapping patterns until the surface looks uniformly polished leaving a slightly dull surface. Wipe with a clean microfiber cloth to inspect. Using a foam pad by hand folded over in half is great for accessing body lines or small areas that a DA sander cannot access. Generally, 2-3 foam pads can sand an entire car before polishing.

Polishing: After the sanding has been completed, it is now time to start polishing the freshly sanded surface. Polishing the vehicle surface requires several steps in order to restore the gloss and depth in the paint. Just like the sandpaper process started from course to finer, the polishing process will follow the same principle.

The first step in polishing the surface is to restore gloss to the entire panel. This is achieved by using a variable speed circular polisher with a wool cutting pad. Using this course pad along with a heavy cutting compound will restore gloss to the surface and polish the sand scratches that were created from the sanding process. This step will also allow for inspection of any missed flaws. It has been found that a lower speed such as 1000-1800 rpm's works well to restore gloss without too much heat transfer. It is also a good idea to tape any adjacent surfaces with masking tape to insure that no damage or "burning through" will occur to the panels next to the one being polished on.

After the gloss has been restored, it will look dull with small polishing marks in the surface. This is normal for this step. The next step is to change to a foam-polishing pad and also change to a medium-polishing compound to deepen the gloss. This step will deepen gloss and allow better visibility. It will also show any remaining sand scratches that may still be visible. In some cases, this step may need to be repeated to achieve a uniform gloss and a scratch free finish.

To further deepen the gloss level, use the same variable speed circular polisher with a finer foam-polishing pad along with a finer polishing compound. This step will remove any remaining polishing marks in the surface and prepare the paint for it's final step. To eliminate any "swirl marks", this step may be repeated with a random orbital or DA polisher.

The final step is to apply a hand glaze. A hand glaze is a wax free protective coating applied to newly painted finishes that are less than 90 days old. A hand glaze allows the paint to properly breathe, allows solvents to evaporate and permits the paint to properly harden. Hand glazes are applied one panel at a time by using a soft polishing cloth. Be sure not to allow a hand glaze to dry on a painted surface. It will make it more difficult to remove.

Color sanding and polishing can easily transform a normal repaint into an exceptional one. The process is involved, however the results are worth the effort. In many cases, others looking at a vehicle that has been color sanded and polished, will often ask, "Who painted it?" Just smile, you know better.